Japanese construction machinery company manufacturer Komatsu will develop fully unmanned construction machinery. While construction machinery capable of automated land preparation and excavation operations already exists on the market, basic operations such as driving the machinery on site still require human intervention. Komatsu will invest in ZMP, a startup developing autonomous vehicles and robots, to absorb these technologies and promote the practical application of next-generation construction machinery.

ZMP, a startup with strengths in image recognition and sensor technologies, is collaborating with Nagoya University to advance the development of autonomous vehicles, including road tests. Komatsu’s investment in ZMP is believed to be in the hundreds of millions of yen, representing less than 5% of the company’s capital. Komatsu and ZMP will collaborate on the development of autonomous and unmanned technologies for construction and mining machinery. By leveraging Komatsu’s long-standing expertise in construction machinery control, they aim to develop construction machinery that can be driven and operated autonomously.

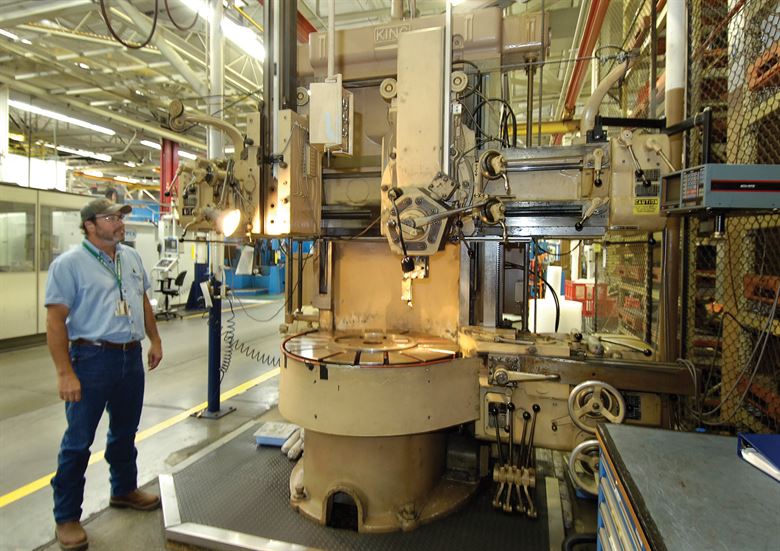

Komatsu has been actively developing unmanned and automated machinery company using technologies such as the Global Positioning System (GPS) and sensors. In 2008, Komatsu developed an unmanned operation system for ultra-large dump trucks, enabling efficient operation on fixed routes within mines. Between 2013 and 2014, the company launched bulldozers and excavators that, while still requiring a human operator, automated land preparation and excavation operations, enabling even novice operators to perform complex tasks.

Compared to mining, construction sites have many variables, including complex routes. If unmanned construction machinery company were to be expensive due to the high development costs, it would be difficult to achieve cost reductions in construction. Therefore, only operational automation has been achieved so far.

Komatsu’s unmanned dump trucks and autonomous construction machinery utilize GPS positioning information for control. ZMP, on the other hand, has an advantage in its technology, which utilizes cameras and sensors to understand surrounding conditions, independent of GPS. The two companies will collaborate to enhance product capabilities.

In addition to autonomous construction machinery, Komatsu has also launched new services since February that utilize IT technologies such as unmanned helicopters and cloud computing to improve productivity and safety at construction sites. Komatsu’s research and development efforts stem from the growing demand for reconstruction and the replacement of aging infrastructure in the aftermath of the Great East Japan Earthquake. Meanwhile, labor shortages are becoming increasingly severe due to factors such as a declining birthrate and an aging population.

As Japan’s working-age population is expected to continue to decline in the future, the company plans to develop unmanned construction machinery company that can improve on-site work efficiency.