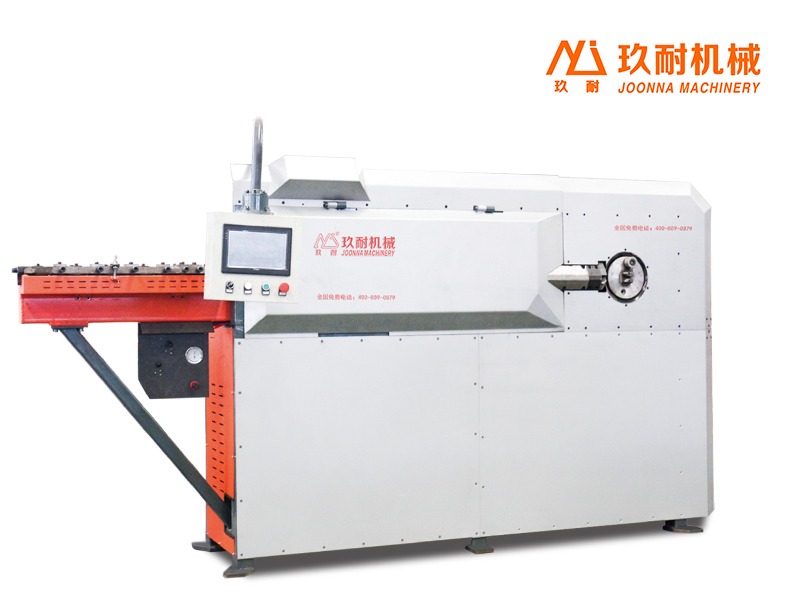

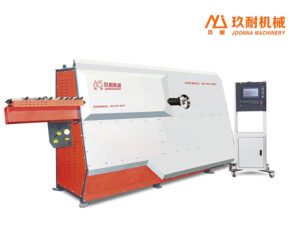

Technical parameter :

| product model | SWG12J | ||

| Ordinary carbon steel single wire processing range (mm) | Φ5-12 | Bending direction | two-way |

| Grade ⅲ threaded steel single wire processing range (mm) | Φ5-10 | Length accuracy (mm) | ±1 |

| Double wire processing range of ordinary carbon steel (mm) | Φ5-10 | Angle accuracy (°) | ±1 |

| Grade ⅲ rebar double line processing range (mm) | Φ5-8 | aggregate capacity (kw) | 11+5.5+4.5+7.5 |

| Maximum bending Angle (°) | 180 | Host exterior dimensions (mm) | 3650*850*1950 |

| Maximum feed speed (mm/s) | 1200 | working temperature (℃) | -5-40 |

| Maximum bending speed (°/s) | 1000 | Airway pressure (map) | ≥0.6 |

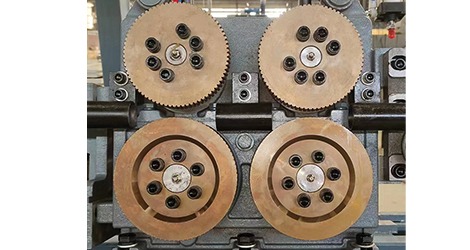

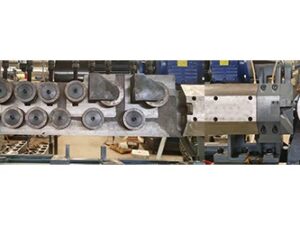

Friction feeding mechanism No slipping, no injury to the ribs

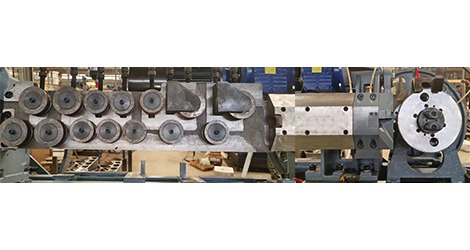

Adopt CNC servo control system Achieve full automation Continuous bending and forming process

Rebar straightening, sizing, bending and cutting The functions are perfectly combined

At the same time, it meets the precision requirements of steel processing Realize one machine for multiple purposes

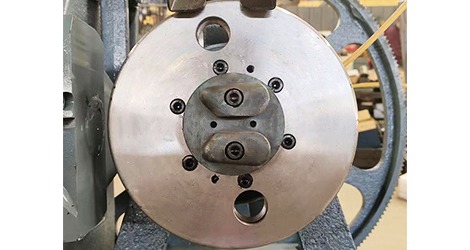

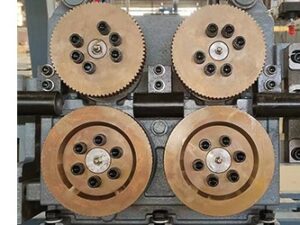

Disk bending mechanism The collision of the hoop reinforcement is avoided The pass rate reached 100%

The traction wheel is provided with an anti-slip groove Prevent steel bars from slipping during processing

End key anti-loosening fastening technology And is equipped with an encoder Ensure the precisionprecision of steel bar delivery ±1mm

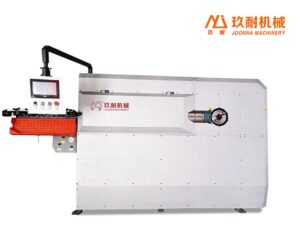

Improved service life The four sides are designed with a movable knife Service life increased by 4 times

Great cost reduction

Reviews

There are no reviews yet.