Rebar cutting machine operating procedures

The work surface for receiving and feeding materials of the steel bar cutting machine should be kept level with the bottom of the cutter. The length of the work surface can be determined according to the length of the material to be processed.

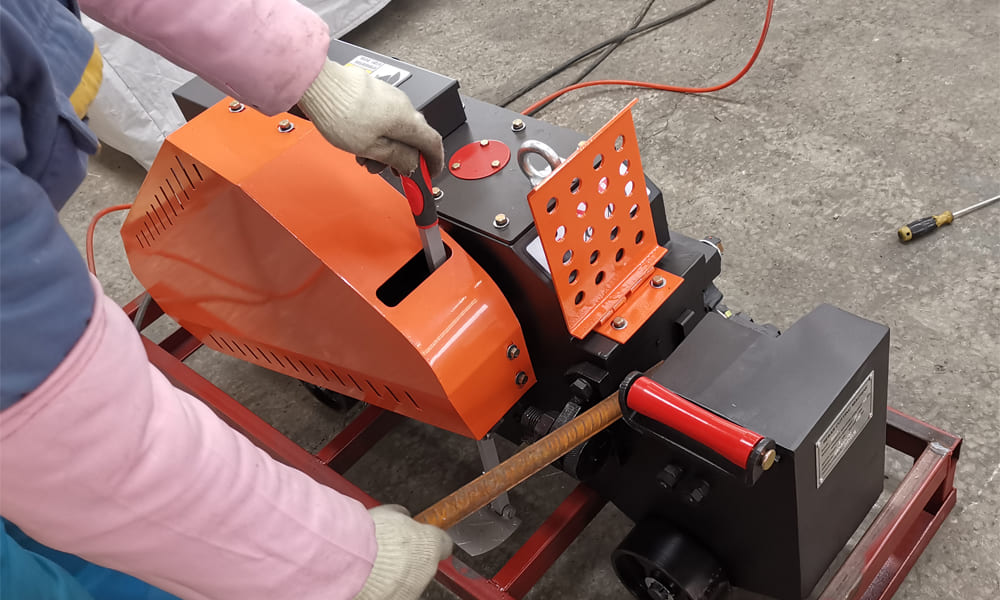

2. Before starting, check and confirm that the cutter is free of cracks, the cutter holder bolts are tight, and the protective cover is secure. Then, manually rotate the pulley to check the gear meshing clearance and adjust the cutter clearance.

3. After starting, the machine should be run dry first to check that all transmission parts and bearings are operating normally before operation.

Do not cut materials before the steel bar cutting machine reaches normal speed. When cutting, use the middle and lower parts of the cutter, firmly grasp the rebar, align it with the cutting edge, and quickly insert it. The operator should stand on the side of the fixed blade and firmly press the rebar to prevent the end from popping out and causing injury. It is strictly forbidden to hold the rebar with both hands on either side of the blade or lean over to feed the material.

5. Do not cut steel bars whose diameter and strength exceed those specified on the machine nameplate or red-hot steel bars. When cutting multiple steel bars at a time, their total cross-sectional area must be within the specified range.

6. When shearing low alloy steel, high hardness cutters should be replaced and the shearing diameter should comply with the specifications on the machine nameplate.

7. When cutting short pieces, the distance between your hand and the cutter should be kept at least 150mm. If the hand grip is less than 400mm, use a sleeve or clamp to press or clamp the short end of the steel bar.

8. During operation, it is strictly forbidden to remove broken ends and debris directly near the cutter with your hands. Non-operating personnel are not allowed to stay around the swinging steel bars and the cutter.

9. If the machine is found to be operating abnormally, making unusual noises, or the cutter is tilted, stop the machine immediately for inspection and maintenance.

10. After operation, turn off the power supply, use a steel brush to remove debris between the cutters, and clean and lubricate the entire machine.

Before operating the hydraulic drive steel bar cutting machine, check and confirm that the hydraulic oil level and the motor rotation direction meet the requirements. After starting, it should run without load, the oil valve should be loosened, and the air in the hydraulic cylinder should be exhausted before cutting.

12. Before using a manual hydraulic cutter, tighten the drain valve clockwise. After cutting, immediately loosen it counterclockwise. During operation, hold the cutter steady and wear insulating gloves.