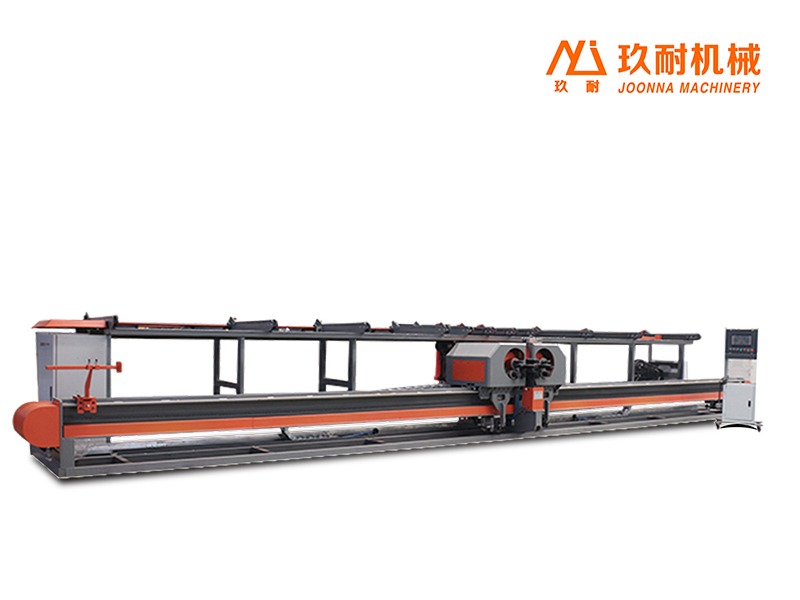

Technical parameter :

| product model | G2LW32B | ||

| Bending speed (r.p.m) | 0-9 | Minimum bending bar length (mm) | 700 |

| Mobile speed of bending machine (m/s) | 0.5-1 | Bend in both directions (up or down) | Φ10-28 |

| source | 350v-50hz | Unidirectional bending (upward bending) | Φ10-32 |

| aggregate capacity (kw) | 20 | Bending steel bar diameter (HRB335) | 10/12/14/16/18/20/22/25/28/32 |

| Actual power consumption (kw/h) | 4 | Number of bends (roots) | 6/5/4/3/2/2/2/1/1/1 |

| Maximum bending Angle (°) | Upwardly curved 0~+180

Bend downward 0-120 |

Speed adjustment mode | CNC servo control, stepless adjustable |

| Minimum length of bending edge (mm) | 80 | Equipment size (mm) | 12050*2100*1500 |

Equipment advantages:

- The curved panel is specially designed to have a long service life.

2. mobile bending machine, bending length free sizing.

- Integrated design, high strength mobile track design, durable.

- Design of bending machine positioning and clamping mechanism to improve bending accuracy.

- The telescopic bending pin shaft realizes the two-way bending of the steel bar.

- High strength material rack, carrying more raw materials.

- The equipment has high performance, and can bend multiple steel bars at one time, and can bend multiple angles without moving.

- Large graph database can preset dozens of graphics for easy retrieval;

- High performance PLC combined with touch screen control interface is easy to operate;

- The design of the central flexible steel bar locking mechanism ensures the bending accuracy.

- High production efficiency, the average processing capacity of 2 people (8 hours) per shift is more than 10 tons, which is more than 5 times that of traditional processing equipment.

- The equipment has good adaptability and can process grade 3 rebar (HRB400) with diameter of 10-32.

Reviews

There are no reviews yet.