Technical parameter :

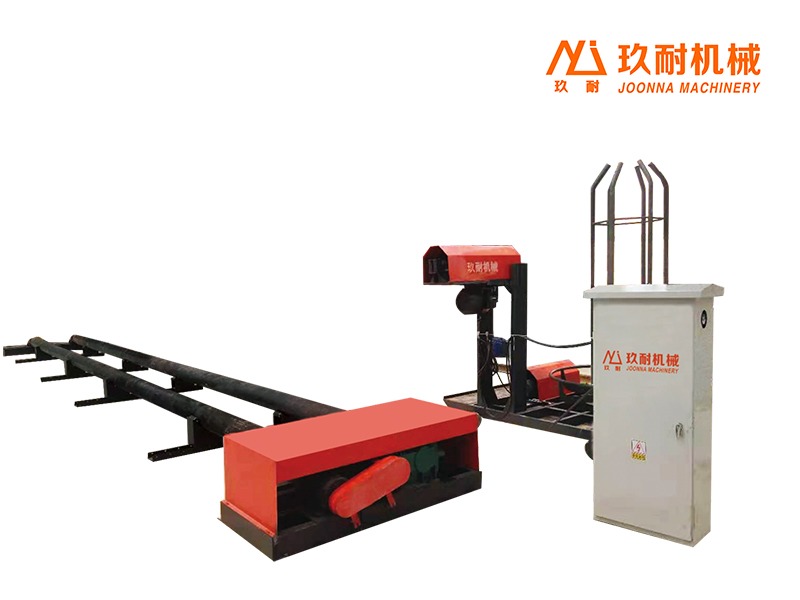

| product model | GJRJ3000 | ||

| Speed of winding (m/min) | 0-15.4(i=59*1.25=73.75) | Car speed (m/min) | 0-1.38(i=593) |

| Rubber roller motor (kw) | 4(Y90L-4) | Motor of small vehicle (kw) | 2.2(Y90L-4) |

| Weight of the machine (kg) | 4500 | Main engine size (m) | 13*1.8*0.8 |

| installation size (m) | 16*14 | Car size (m) | 15*1.3*1.5 |

| range of work (m) | Φ 0.4-3, length 12 | ||

Equipment advantages:

- The rebar cage hoop machine has a wide range of processing, suitable for the design requirements of various main hoops in quantity, form, model, size and length, and will not affect the design of the rebar cage or fail to be produced on the machine due to the function of the equipment.

2, mechanized operation is not affected by human factors, long-term work can be stable. The quality is stable.

- The products made by the rebar cage winding machine are compact in structure and beautiful in shape.

- Fast forming speed, two standby states can be fully produced, and 3-6 people can produce more than 10-20 sections of steel cages a day under normal working conditions.

- The assembly line operation form allows independent construction without being affected by the process, and completes the whole process of welded main stirrup and hoop formation and welded stirrup winding process without interruption.

- The combined design makes the handling, installation, sound field and other processes not dependent on lifting equipment, and is suitable for large-scale fixed production in factories and decentralized machine operation at construction sites.

- The surrounding tendon can be made at the same time as the main tendon.

Reviews

There are no reviews yet.