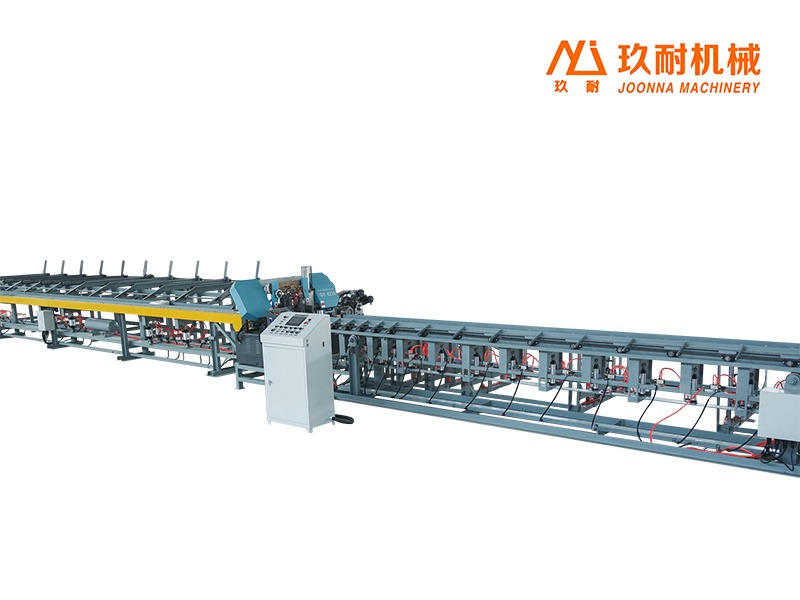

Technical parameter :

| product model | JN-120KN | ||

| Cutting rebar range (mm) | Φ12-40 | Cutting accuracy (mm) | ±2 |

| Roller conveyor speed (m/s) | 1.5 | power (kw) | 25.5 |

| Reinforcement length range (mm) | 1000-12000 | outline dimension (mm) | 28000*3300*2500 |

| Working pressure (mpa) | 31.5 | weight of equipment (kg) | 7000 |

| Cutting frequency (mm/s) | 20 | Steel diameter shear (mm) | Φ12/16/20/25/28/32/40 |

| Electrical control systems | 380v/50-60hz | Rooted device model | 15/12/10/8/6/4/1 |

Equipment advantages:

Imported PLC and CNC control shear precision, high degree of automation, finished product accuracy.

Anti-jump automatic clamping device, high safety.

Multi-stage finished product storage organization to ensure high life expectancy.

Modular combination, according to the requirements of different configuration modes.

The bidirectional discharge design doubles the amount of finished products stacked.

The design of mobile material platform greatly reduces labor intensity

Reviews

There are no reviews yet.