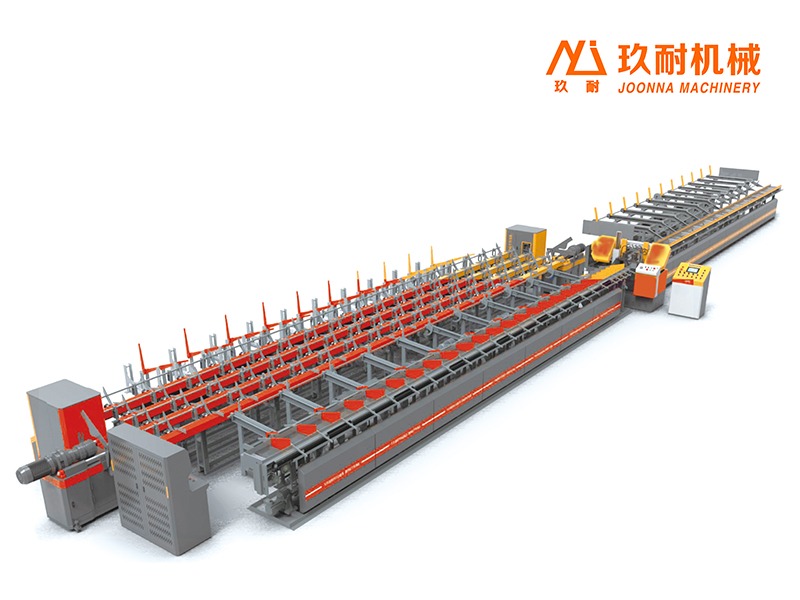

Technical parameter :

| product model | JN-450L | ||

| Maximum processing diameter round steel (mm) | ≤50 | Single head grinding time (s) | 3-5 |

| Steel bar conveyor speed (m/min) | 58-62 | Storage bin level | 3*2 |

| Maximum length of shipping line (mm) | 12000 | working voltage (v) | 380 |

| Maximum length of feed line (mm) | 12000 | Total power/total power consumption (kw) | 40 |

| effective width (mm) | 450 | working temperature (℃) | -10-50 |

| Steel bar transmission speed (m/min) | 58-62 | Working pressure (mpa) | ≥0.4 |

| Pouch length (mm) | ≤90 | Complete set of self-repairing equipment (t) | 18 |

| Single tube threading time (s) | 25-40 | bar diameter (mm) | Φ16/20/25/28/32/35/40/45/50 |

| Diameter range of sleeve wire (mm) | Φ16-40 | Quantity of steel bars | 28/22/18/16/15/12/11/10/9 |

Equipment advantages:

Fast processing speed: this machine reduces auxiliary labor, reduce labor costs, use processed products thread standard, accurate size, high efficiency, simple installation, easy to use.

Long service life: the raw materials of the whole machine are polished by large shot blasting equipment, sandblasting, primer and topcoat process, which greatly prolongs the service life of the equipment.

Site saving: this set of wire cutting equipment can be connected with the steel bar shear saw cutting equipment. After cutting the steel bars to the specified length, the steel bars can be directly entered into the wire cutting equipment without occupying the site to store the steel bars.

Reduce labor: the equipment operator only needs one person to complete the operation, no need to lift and carry the wire directly transported.

Module equipment: The equipment is composed of two key parts, the upsetting and the threading. At the same time, these two parts can be separated and used as independent equipment.

Reviews

There are no reviews yet.