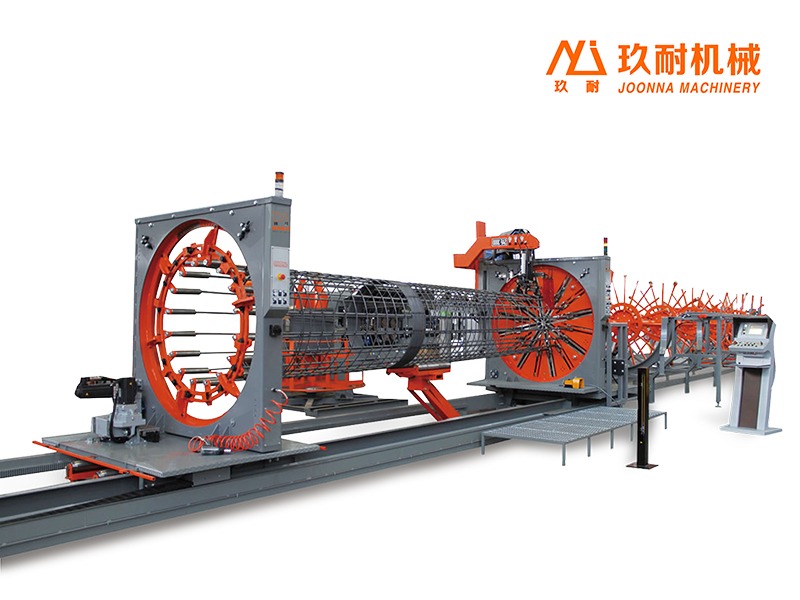

Technical parameter :

| product model | JN-HLJ | ||

| Pile diameter (mm) | 600-2000 | Maximum rotation speed (r/min) | 5 |

| Reinforcement cage length (M) | 2-12 (customizable) | Reinforcement cage diameter error (mm) | ±15 |

| Maximum weight of steel cage (kg) | 8000 | Walking servo motor (kw) | 4.5 |

| Main diameter (mm) | Φ6-32 | Rolling cage servo motor (kw) | 3 |

| Plate diameter (mm) | Φ6-12 | control method | Industrial PLC+ touch screen HMI |

| Wire spacing (mm) | 50-500 | Rated total power (kw) | 20 |

| Maximum moving speed of mobile turntable (m/min) | 1300 | outline dimension (M) | 27~57*8*3.2 |

Equipment advantages:

- Automatic wire feeding mechanism, which can adjust the distance online with small error and high forming quality.

- Automatic welding, accurate soldering, reduce labor intensity.

- Variable frequency control of drag cage mechanism, high walking precision.

- Automatic cage support design, which can be raised and lowered automatically to support the steel cage and avoid bending deformation caused by the self-weight of the cage during welding.

- Automatic feeding device to speed up the feeding speed and improve efficiency.

- The flexible mold ring and cross rib installation design of the large market can be flexibly replaced according to different pile foundation specifications, which is economical and applicable.

- Flat roller straightening device, good straightening effect and long service life.

- Control system: PLC, touch screen, frequency converter, variable frequency motor.

Reviews

There are no reviews yet.