Metal crushers are widely used in mining machinery and other industries. The working condition of the machine is closely related to the wear-resistant accessories. So how to extend the service life of crusher accessories as much as possible under harsh working conditions?

1. Match the appropriate accessory material according to the performance of the machine’s crushing materials

The harder the stone, the harder it is to crush, the more wear and tear on the equipment, the slower the crushing speed, and the smaller the crushing capacity. The surface hardness of the stone is directly related to the service life of the crusher accessories. Therefore, when purchasing accessories, be sure to select accessories made of the appropriate material based on the properties of the material to be crushed.

2. Choose different crushers according to the humidity, viscosity, temperature and other issues of the material to be crushed

When the material contains a high amount of moisture, it tends to adhere to the crusher and become clogged during the conveying process, reducing crushing capacity. Furthermore, the greater the viscosity of the material, the lower the crushing capacity of the crusher. Choosing the right crusher based on the material’s moisture, viscosity, and temperature can help reduce wear on components and extend their service life.

3. The particle size of the finished product also affects the service life of the accessories

The smaller the required particle size of the finished product, the more contact and friction the material will have with the accessories in the crusher, and the greater the degree of wear will be. The smaller the particle size required for the final crushed stone, the slower the crushing speed, and the smaller the impact on the crushing capacity.

4. Influence of fine powder content in the material to be crushed

The more fines in the material before crushing, the more it affects crushing capacity. This is because fines tend to stick to the conveyor belt during transportation, affecting material transport, directly affecting the crusher’s feed rate and feed rate, and significantly reducing crushing efficiency. Materials with high fines content should be screened beforehand. Furthermore, the more impurities in the material, the lower the crushing capacity.

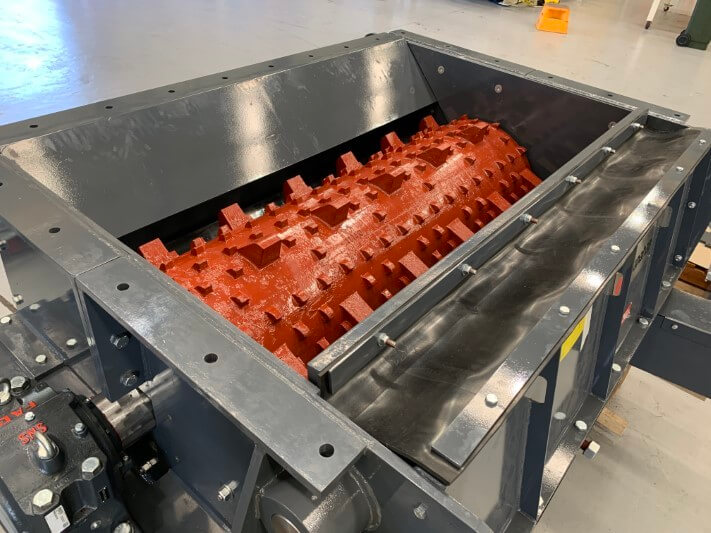

5. Quality issues of metal crusher accessories

To choose high-quality, wear-resistant accessories, you need to choose a professional wear-resistant parts manufacturer. Good quality can last a long time.